Digital fabrication

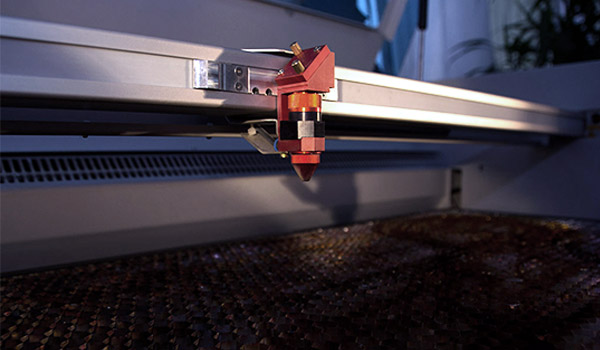

LASER CUTTING

Laser cutting is a subtractive manufacturing method that uses a digital drawing to cut or engrave materials.

The laser can operate in 2 modes: raster or vector. Raster files (like a .jpg .gif or an image format) will make the laser behave a bit like a traditional printer, where the head is moving along the x-axis of the sheet and rendering the image slowly up and down the y-axis. This method is only used for engraving to achieve high precision and details.

The vector mode can be used to engrave or cut through the material. The head of the laser will follow the lines of the vector graphic at a greater speed.

Cutting / Engraving

– Wood

– Plastic

– Acrylic Mirror

– PETG

– Paper/Cardboard

Engraving only

– Anodized metal

– Stainless steel

– Glass

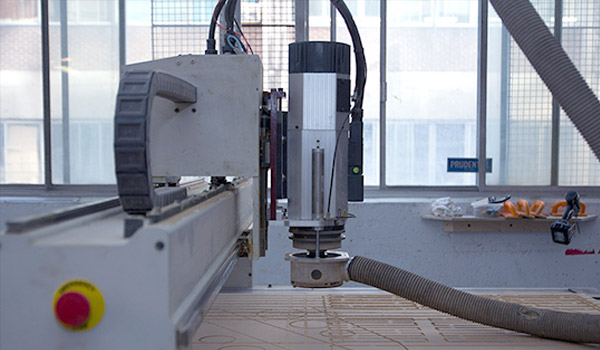

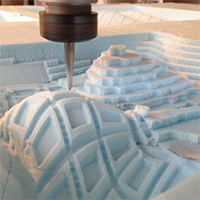

CNC ROUTER

CNC routing is a subtractive manufacturing method that uses a digital drawing to cut or engrave materials.

The CNC router uses a circular tool to remove material from the stock. The router uses a variety of tools that are specially designed for various applications and finishes such as chamfering, double-sided finish on laminates, round-overs, engraving, pen attachments, etc.

Cutting / Engraving

– Wood

– Plastic

– Aluminum

– Brass

– Acrylic Mirror

– PETG

– Machinable wax

– Alucobond

– Foam

– Arborite

– PVC foam

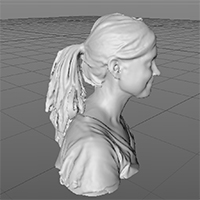

3D PRINTING

3D printing is an additive manufacturing process that uses a digital 3D model to construct an object in successive layers of material. Our printer renders the object in a special type of ABS plastic. The resulting strong and durable pieces can be used in mechanical assembly.

ABS Plus+

Dimensions(Build size):

The model can be built up to 8in / 8in / 6in

Layer thickness:

– 0.1MM

Format supported:

– STL

(no interpenetration on the models or inverted normals on the geometry)